Stock code:839470

+86-021-56197282

+86-021-56197282

Product Introduction

Product Introduction

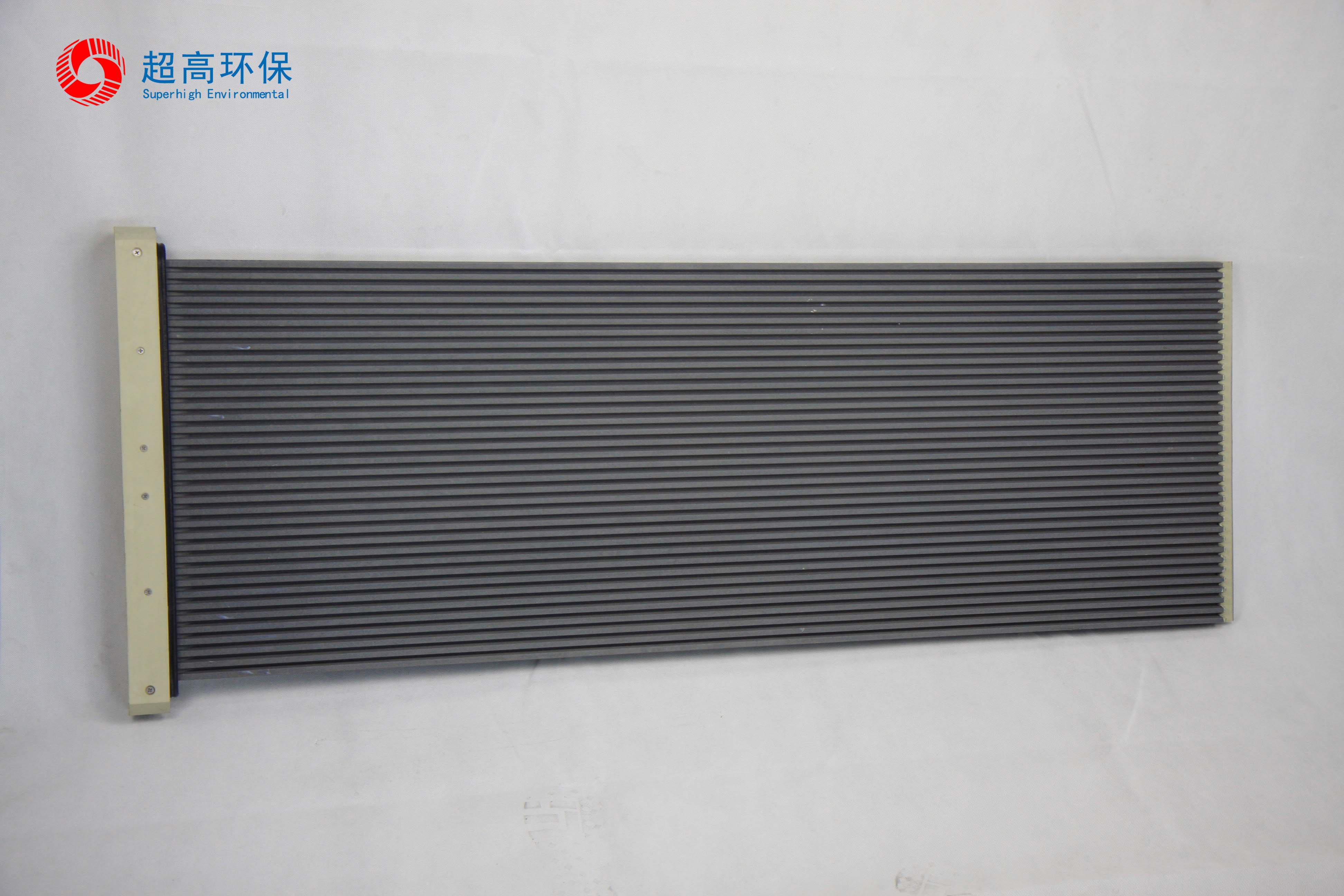

This revolutionary filter element designed and patented by Shanghai Super Environmental Protection Technology Co., Ltd. is a new concept for filtration equipment design and the largest breakthrough in filtration technology over the past 50 years.

Its special configuration allows the filter surface to be up to three times higher than conventional filters, and even the most difficult products provide efficient filtration.

In the pharmaceutical industry, the food industry, epoxy coatings, pigments, polishing and grinding, wet enamel, cement, abrasives, corundum recycling, shot peening powder, laser or plasma cutting powder applications.

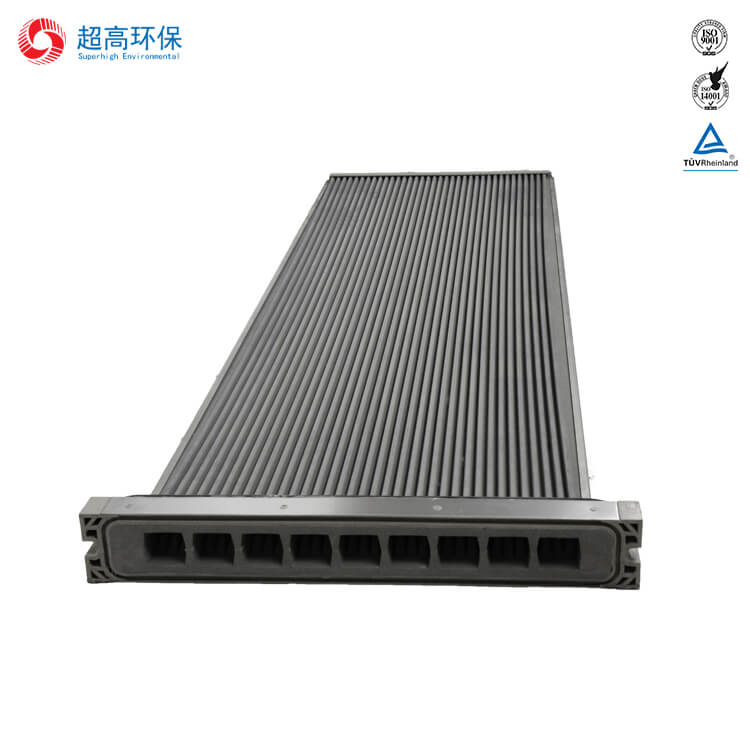

Unique structure

The sintered plate filter element has a rigid wave type multi-empty structure, and is sintered by a plurality of polymer compound powders and a special binder, and forms a wave type multi-air matrix as a substrate of the sintered plate filter element. The substrate is about 4 mm thick, and a uniform void of about 30 μm is formed inside, and then a PTFE coating is filled in the gap of the surface of the mother by a special spraying process.

Product performance characteristics

●The dust removal efficiency is up to 99.99%, which can effectively remove dust above 0.1 microns. Purification value is less than 1mg/m3;

●Unique structural design, service life of more than 10 years;

●The filtering wind speed is high, the effective filtering area is large, and the volume is only 1/3 of the traditional bag filter;

●Resistant to acid and alkali, moisture and abrasion;

Constant pressure drop

Since the wave-type sintered plate captures the dust through the surface of the PTFE coating, its smooth surface makes the dust extremely difficult to penetrate and stay, even if some fine dust may enter the gap, it can be set. The pulsed compressed air is blown away. Therefore, no clogging phenomenon occurs in the mother layer of the filter plate, and the pressure loss of the filter element tends to be stable and remains unchanged after a short period of time. This indicates that under certain temperature conditions, the resistance loss is only related to the filtered wind speed and does not rise with time. Therefore, the processing air volume after the operation of the dust collector will not change with time, which ensures the stability of the process.

Water resistant oil, can be washed directly with water

The sintered plate base material and the PTFE coating have complete hydrophobicity, and do not cause a water film to form due to moisture absorption of the fiber fabric filter bag, thereby causing a sharp rise in resistance. The sintered plate can be directly washed with water, which brings great convenience to the process of frequently changing the production products, such as chemical production, pharmaceutical, electrostatic powder coating, etc., without replacing the filter material, it is only necessary to directly rinse the sintered plate with water. can.

Good antistatic properties

By spraying a good conductive material on the surface of the sintered plate and passing through the integral molding and sintering process, the sintered plate filter element has good electrical conductivity, and at the same time, in each part of the design, manufacture and installation of the overall dust removal device, each part is Equipotential bonding and good grounding ensure installation during production, which is critical for flammable and explosive dust handling.

Extremely convenient maintenance

Although the filter elements of the sintered board dust collector have almost no maintenance, in special industries, such as the color variety change during the production of pigments, the paint replacement in the spray industry, and the regular disinfection in the production of pharmaceutical foods, the filter plates need to be removed for cleaning. . At this time, the special structure of the sintered plate dust collector will make this work very easy, the operator can operate outside the dust collector, and the two filters can be replaced by replacing two bolts, and the working conditions are fundamentally improved.

long lasting

The sintered plate has a rigid structure, which eliminates the life problem caused by the wear of the fiber fabric filter bag due to the skeleton. Another important performance of long life is that the filter has a trouble-free running time and it does not require frequent maintenance and maintenance. Good cleaning properties will maintain its constant resistance, so that the sintered plate dust collector can work efficiently for a long time and has a service life of more than ten years.

The sintered plate achieves complete surface filtration with a discharge of 1 mg/m3. The base of the sintered plate is sintered from a plurality of polymer materials with different densities. The PTFE coating penetrates into the pores of the sintered plate base and forms an ultra-fine microporous anti-adhesive structure, which has good chemical corrosion resistance. The HSL sintered plate has a very stable structure, strong rigidity, hydrophobic and oleophobic, low maintenance cost and an average service life of more than 10 years.

Sintered plates have extremely high collection efficiency and good environmental coordination. Sintered plates can be regenerated without any waste or toxic waste. HSL series dust collectors have good stability and rigidity, excellent wear resistance and tear resistance for abrasive dust, compact structure, optimized process design, excellent emission index and high operational safety. The filter plate can be back-flushed and cleaned by timing control or differential pressure control. The filter plate is fixed with 2 bolts for easy maintenance and time saving. Antistatic or other special designs can also be used as needed, such as aerosols.

Product Superior

Product Superior

feature

Drying process: dry collection and disposal.

Guaranteed emission value: less than 1mg/Nm3.

Large filter area in a small space.

Low pressure drop.

High moisture resistance.

Highly corrosion-resistant products.

Supports dust loads in excess of 250gr/m3.

Wear-resistant, minimal wear.

Life more than 10 years.

The maximum working temperature is 110°C.

If you do not want to come into contact with the product (if it is harmful or toxic), install the filter in a clean area.

The best filter media for equipment in the ATEX area.

Application and activity areas

* The automotive industry is welding.

* Manufacturing technology Plastic parts, polyester parts molding.

* Spray booth and surface treatment.

* Cement, quarries and pottery. Dry grinding application.

* The pharmaceutical sector and the food industry.

* Detergent industry.

* Laser cutting cabins for polycarbonate and metal.

* ATEX classification area equipment.

* Manufacture of stainless steel parts, aluminum parts foundry.

* Battery manufacturer.

Product Performance

Product Performance

Sinter-plate filter(Small filter area)Application of Polyethylene

Sinter-plate filter(Small filter area)Application of Polyethylene